A tool that offers multidimensional value

Artificial intelligence and data analysis platform unique to the industrial environment, enabling real-time visibility and actionable insights for machines, lines and factories.

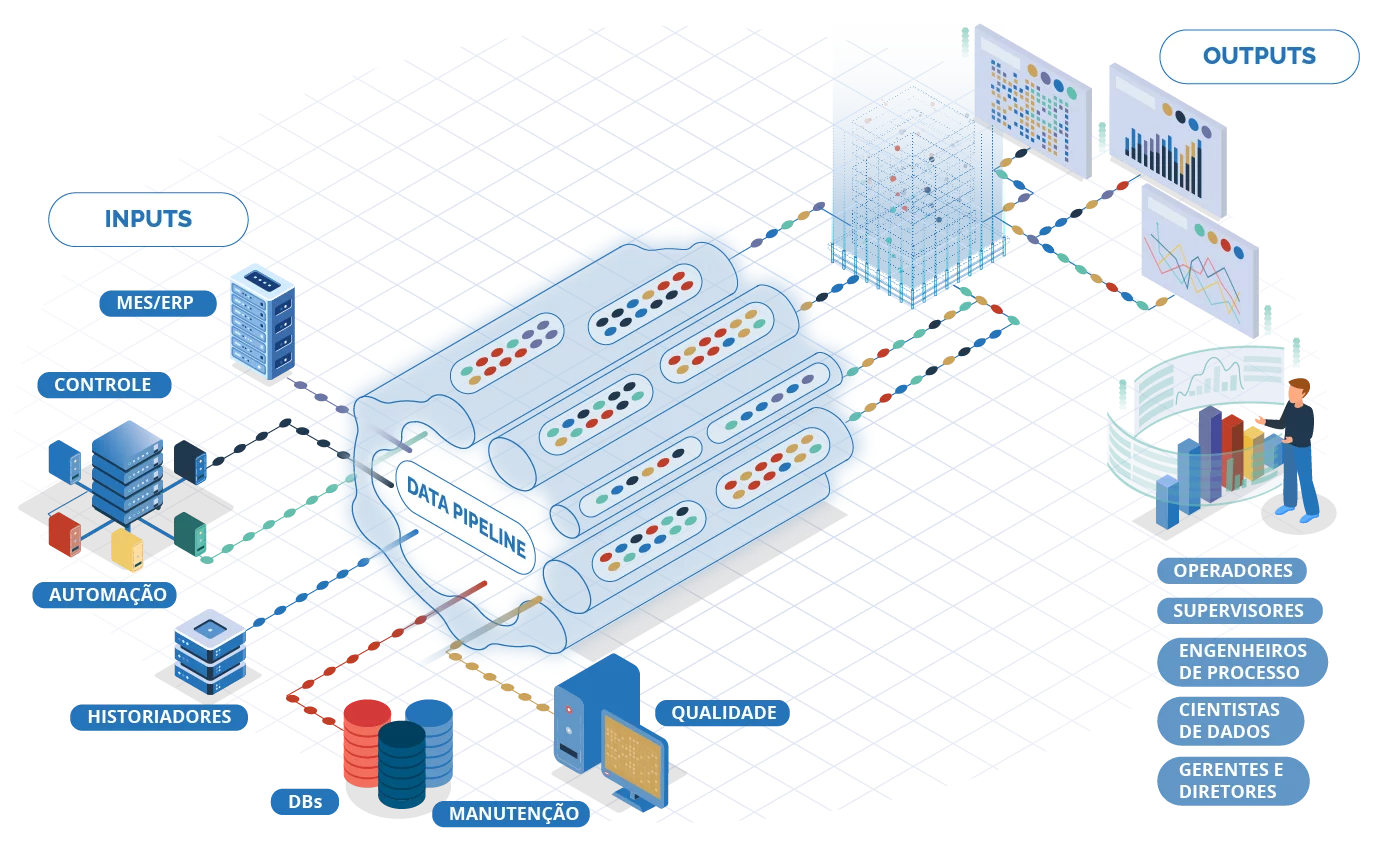

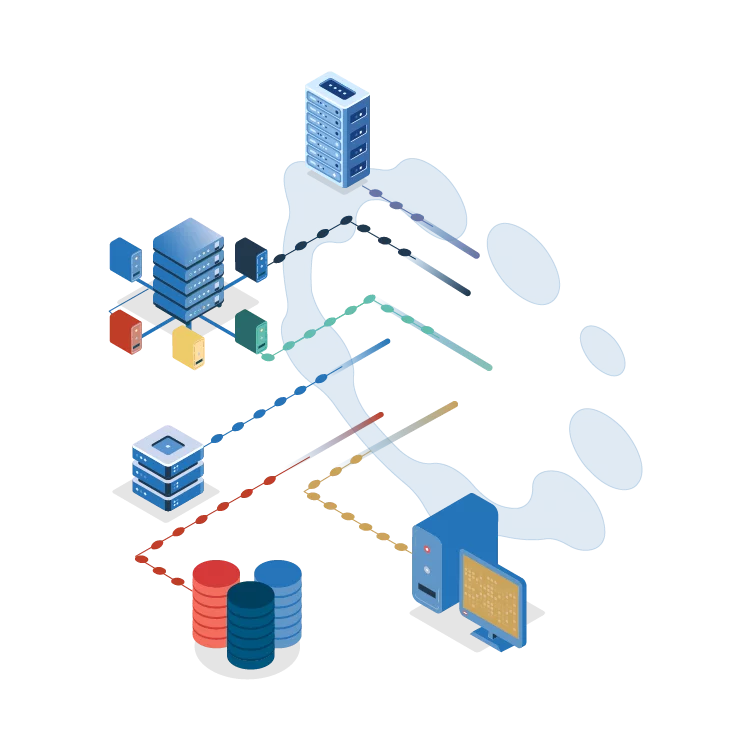

Collecting Data

Connect and normalize the huge variety of data from a shop floor and send it to Crave Platform's Data Pipeline.

Connect your sources and collect data from virtually anywhere.- Historians (PIMS)

- PLCs

- Supervisory Control Systems (SCADA)

- Quality Systems

- Database (SQL)

- MES

- ERP

- Logs

Add minimum data pre-identification contexts and securely transmit your data to the cloud. You can also count on a buffer for transmission management, which is essential in cases of connection instability and bandwidth limitations.

Data modeling

Automatically prepares and contextualizes process, material and quality data. A digital environment is created, configured to faithfully portray your industrial production. Machine learning algorithms and advanced data analysis are then applied to act on problems such as process abnormalities and generate insights for strategic operational actions.

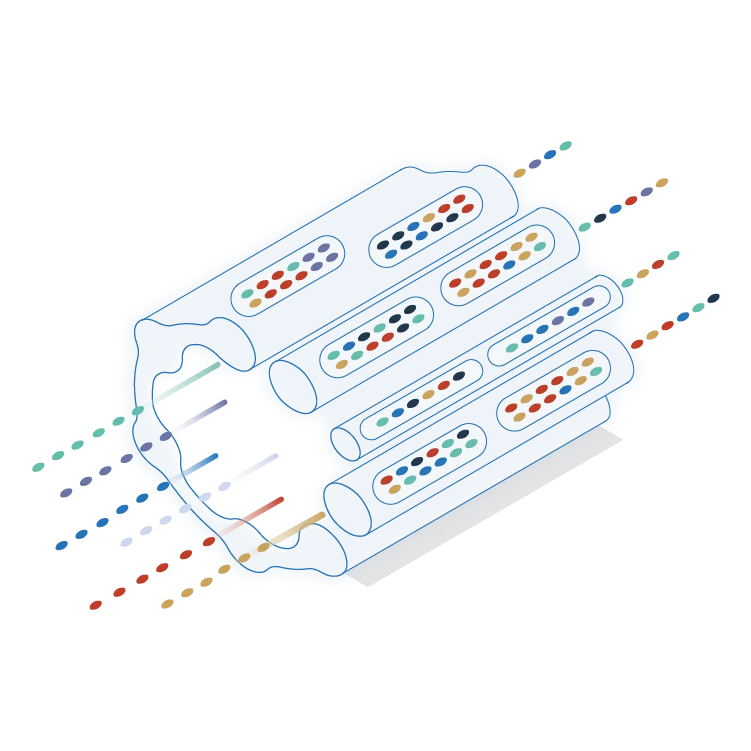

Data Pipeline

Convert unstructured and disorganized data into contextualized data in real time. Data Pipeline is customizable via the web application for parameterization and environment configuration.

Complete control over the manipulation of your data through the intuitive interface for parameterizing actions and enriching data with contextualization. Organize flows, insert parameters used in the production scenario and make information, access and visualizations available to all user levels.

Big Data & Digital Twin

Overview through one platform

Create a faithful replica of your assets, production lines, products and processes.

- Corporation

- Factory

- Area/Line

- Machine/Asset

- Product

- Cycle Time

- Defect

- Batch

- Machine stoppages

Advanced Analysis

Real-time data that supports best practices in quality control, engineering diagnostics, KPI monitoring and production line metrics.

Tools for advanced analysis

Work with new reports, analyses and dashboards that display correlations, distributions and root causes in real time

- Root cause

- Optimization

- Predictive

- Statistical Process Control

- KPIs

- Anomaly Detection

Take Action

It uses analyzed data, provides real-time visibility and actionable insights for machines and production lines in your factory. The Crave Platform presents the right information to the right person.

Your data is completely exported through direct access via ODBC interfaces or HTTP APIs. This allows you to integrate your contextualized data with BI and reporting tools.

Industrial Director

Standardized KPIs and metrics to compare plants and divisions and identify problems and best practices.

Plant Manager

Real-time visibility of all the machines on the shop floor for immediate decision-making.

Machine/Line Operators

Information from sensors, setpoints and actuators as well as KPIs and metrics for the line or machine.

Data Scientist

Access to clean, standardized and contextualized data, available for consultation and safe, fast manipulation.